Connecting Dots: Ignition And The Automation Pyramid

In the rapidly evolving landscape of industrial automation, the ability to connect and communicate across the various levels of an enterprise is critical for achieving seamless operational efficiency and interoperability. However, the diverse array of proprietary field devices used by manufacturers complicates data exchange across these levels.

By visually representing the different levels as an Automation Pyramid, also called the Purdue Model or ISA 95, and describing how the Ignition software platform integrates across all its levels, this post aims to showcase how devices of any brand or type can work together harmoniously — whether you're dealing with field-level devices, controlling devices, monitoring tools, planning systems, or management software.

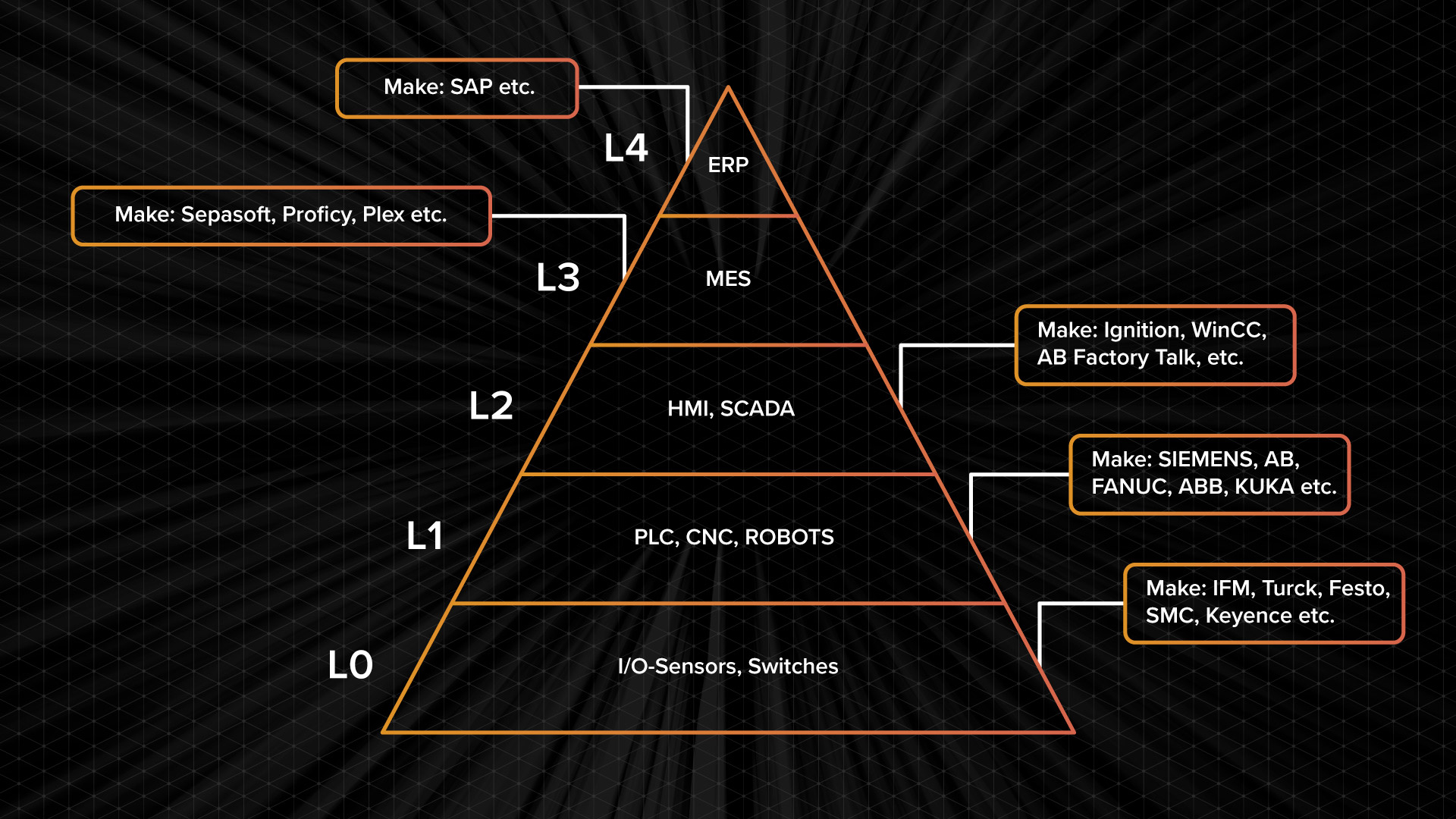

What Is The Automation Pyramid?

It is a method of illustrating how the various devices in an automation system are connected. There are five layers, and each one has a distinct function.

- L0 - Field layer: Devices such as sensors, valves, switches, and motors

- L1 - Controlling layer: Devices such as programmable logic controllers (PLCs), systems like computer numerical controls (CNC), and robots

- L2 - Monitoring layer: Devices such as human machine interfaces (HMIs), or supervisory control and data acquisition (SCADA) systems

- L3 - Planning layer: Manufacturing execution system (MES) to monitor, document, and track the process

- L4 - Management layer: Enterprise resource planning (ERP) system

Now that we know what the Automation Pyramid is and what it looks like, let’s examine how Ignition SCADA integrates with each layer of it.

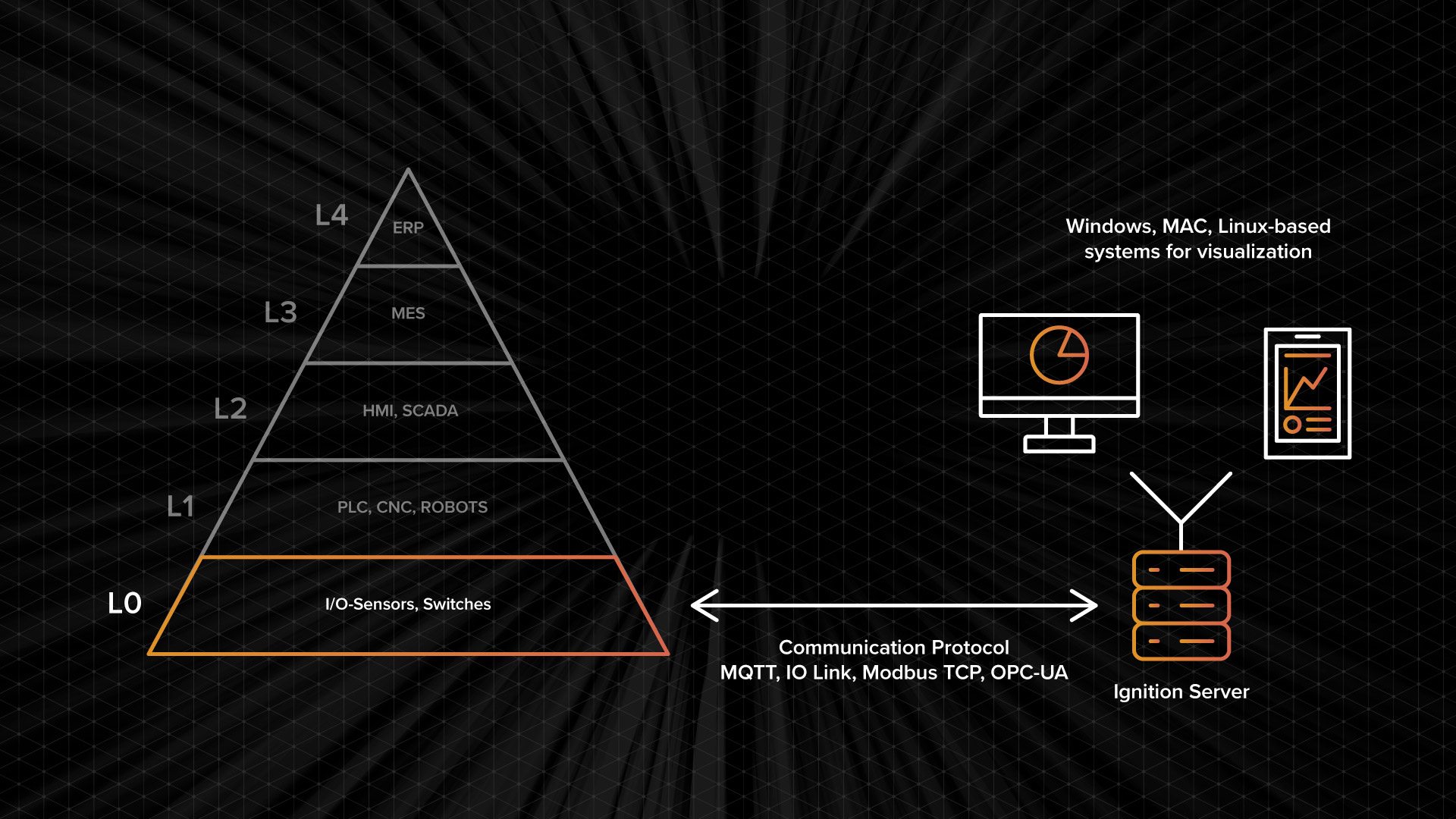

Layer 0: Field Layer

- This level of the Automation Pyramid consists of field-level devices, such as sensors, actuators, vision cameras, scanners, monitoring devices, and other input and output devices.

- Ignition SCADA seamlessly integrates with Level 0 and exchanges the data with protocols like IO Link, Modbus TCP, OPC UA, and MQTT.

- Ignition is fully compatible and interoperable with the Windows, Mac OS, and Linux operating systems, so we can visualize the data from the sensors without that data necessarily being sent to the PLC.

- This means that compatibility and interoperability are assured from the very beginning and from the bottom of the pyramid, as long as these sensors can talk through an open protocol like the ones listed above.

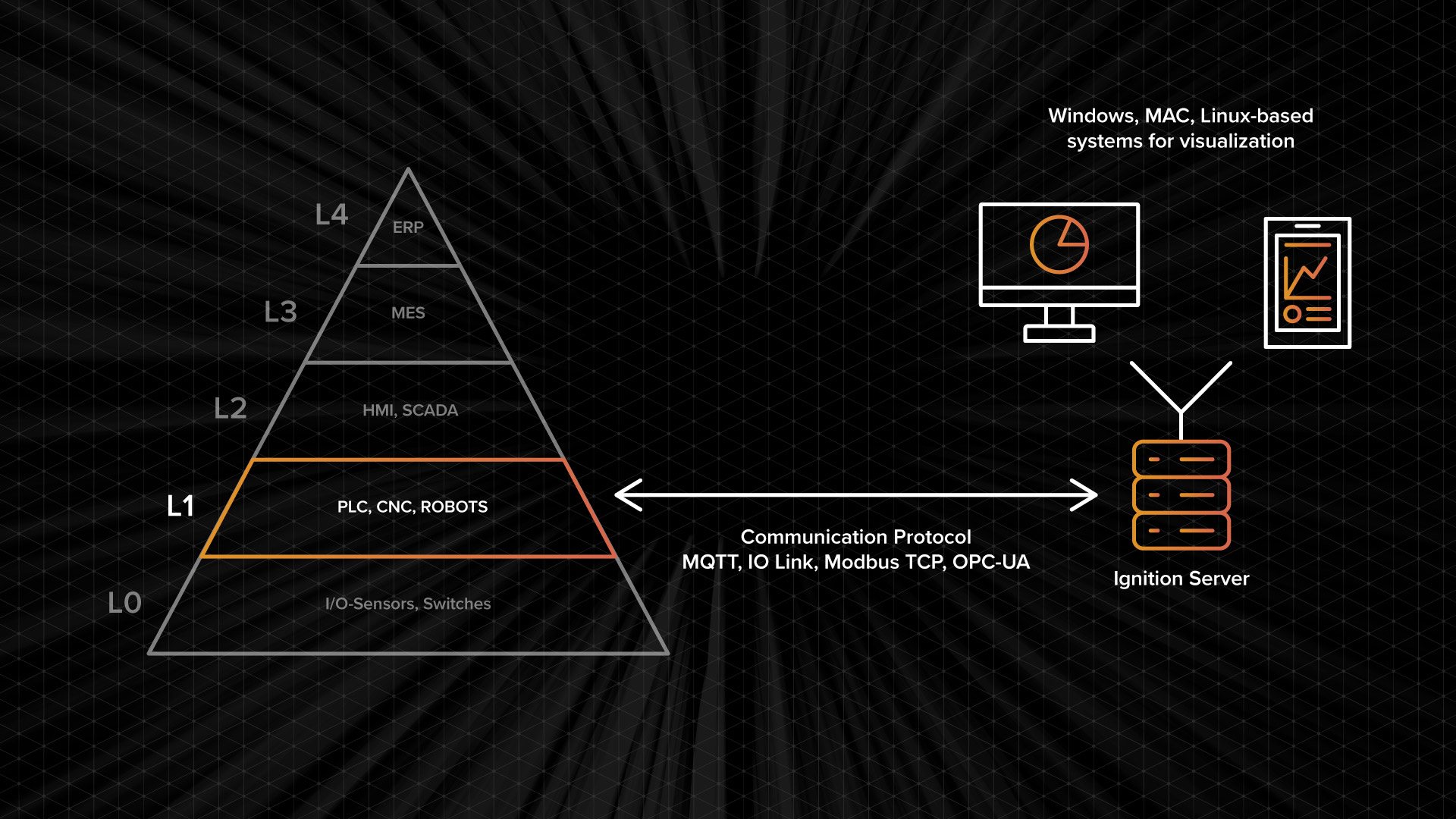

Layer 1: Controlling Layer

- PLCs, robot controllers, CNC controllers, and other controlling devices make up Level 1.

- Ignition SCADA seamlessly integrates with Level-1 controlling devices with the interoperable protocol stack like Siemens, Allen Bradley, Mitsubishi, and more.

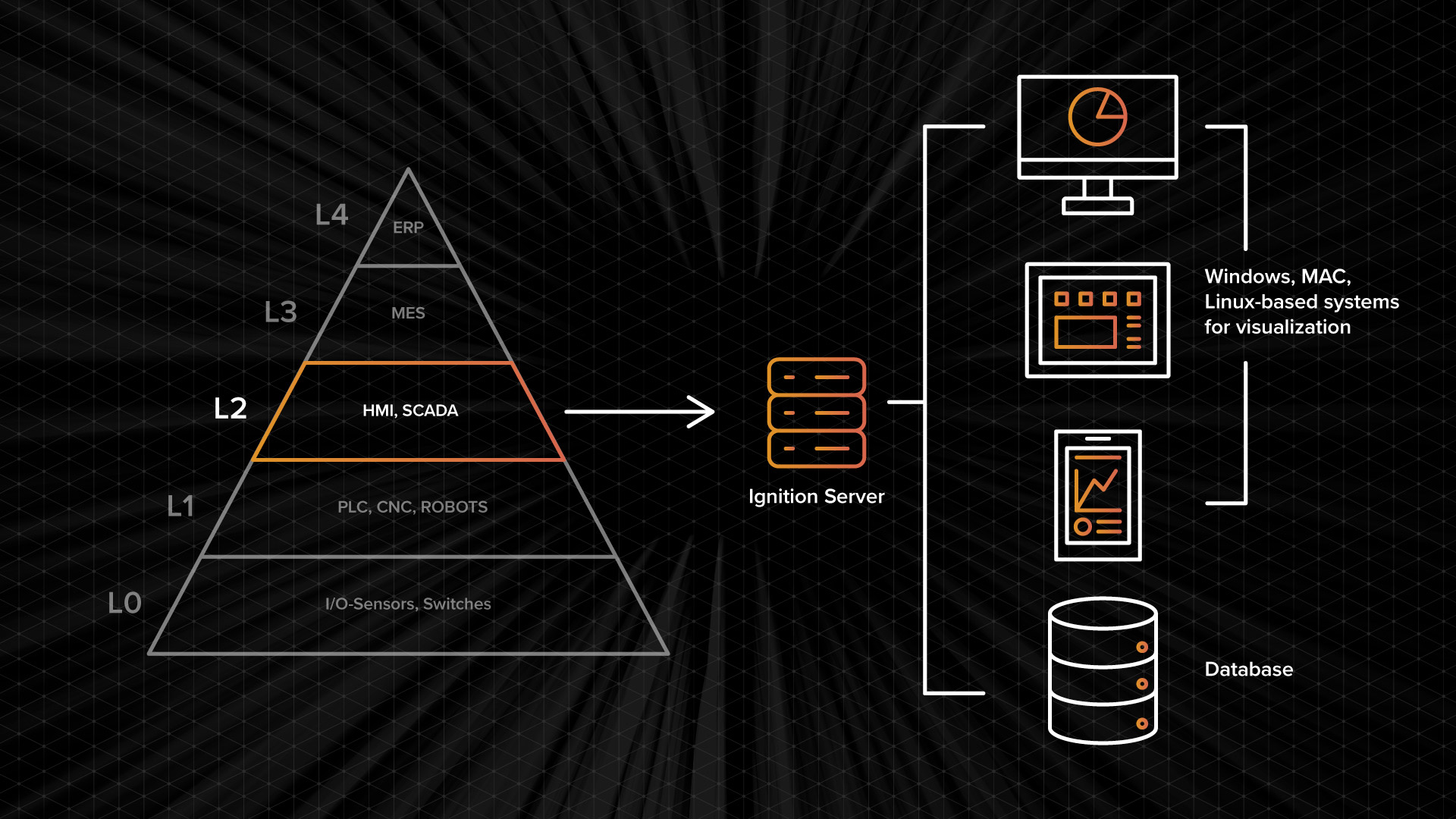

Layer 2: Monitoring Layer

- Level 2 includes databases, touch panels, mobile devices, PCs used for dashboarding, and other visualization tools.

- Ignition integrates very well with many different HMI/SCADA visualization formats. With the power of the Perspective Module, the end user can view and control data from any device that supports a web browser, such as Chrome, Edge, or Safari. iOS and Android apps are another option for native application functionality on phones and tablets.

- For data storage and reporting needs, it integrates well with SQL databases, like MSSQL, PostgreSQL, Oracle, and more, using a JDBC driver. Ignition also has the capability to integrate with MongoDB as well using Ignition's MongoDB Connector for non-relational data.

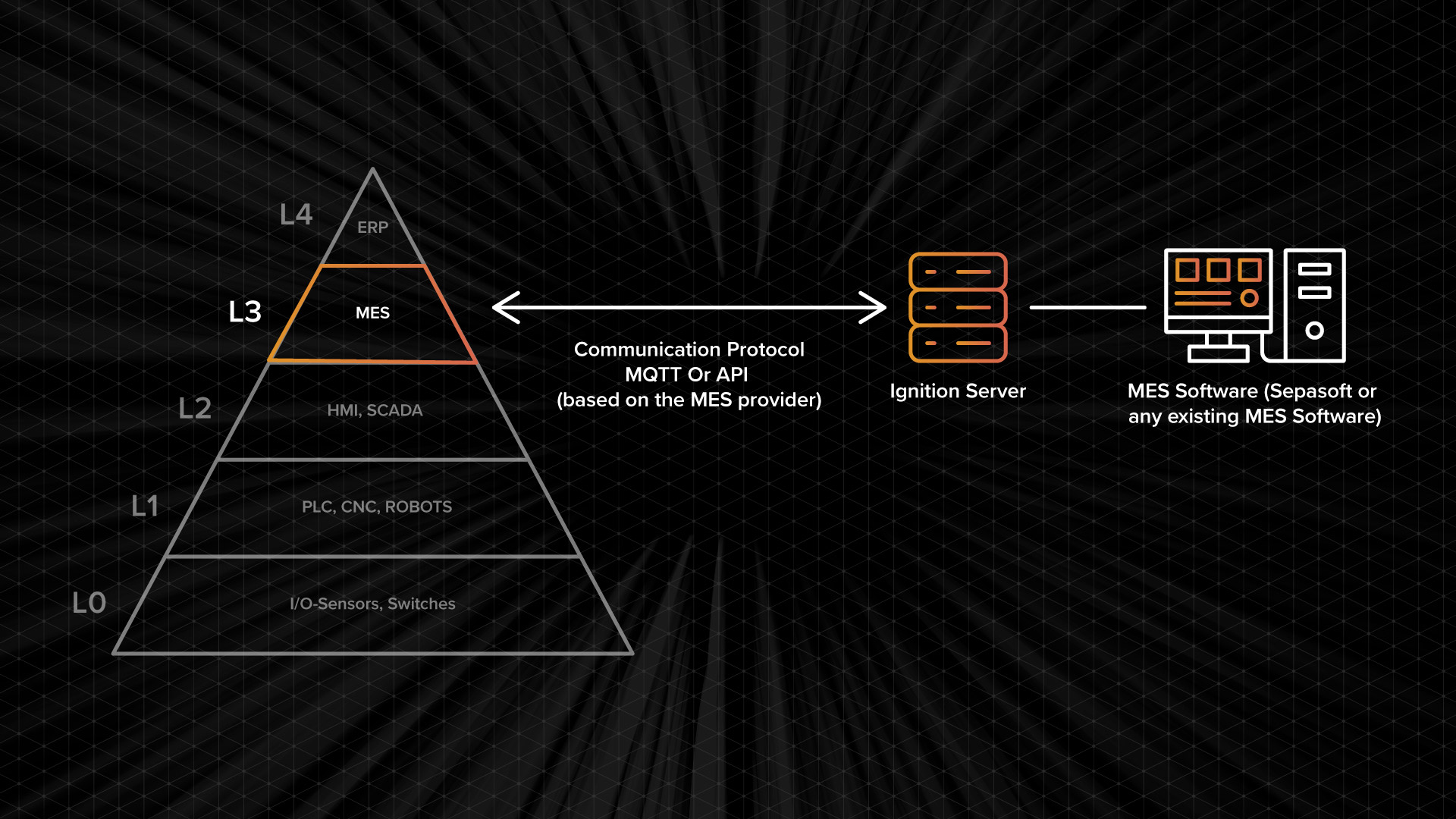

Layer 3: Planning Layer

- Level 3 is also known as the Planning or MES Level.

- From the raw ingredients to the final product, MES not only keeps an eye on every step of the manufacturing process but also tracks inventory, updates consumptions, generates operator work instructions, manages product flow, and more throughout the factory or plant.

- To help kickstart the MES solution in Ignition, Sepasoft, one of Inductive Automation's Solution Partners, creates MES modules using Ignition's Module SDK for seamless integration with the Ignition platform.

- For proprietary MES, Ignition can connect by using REST or SOAP APIs, common databases, or a suitable protocol like MQTT (based on the services available from the proprietary MES provider).

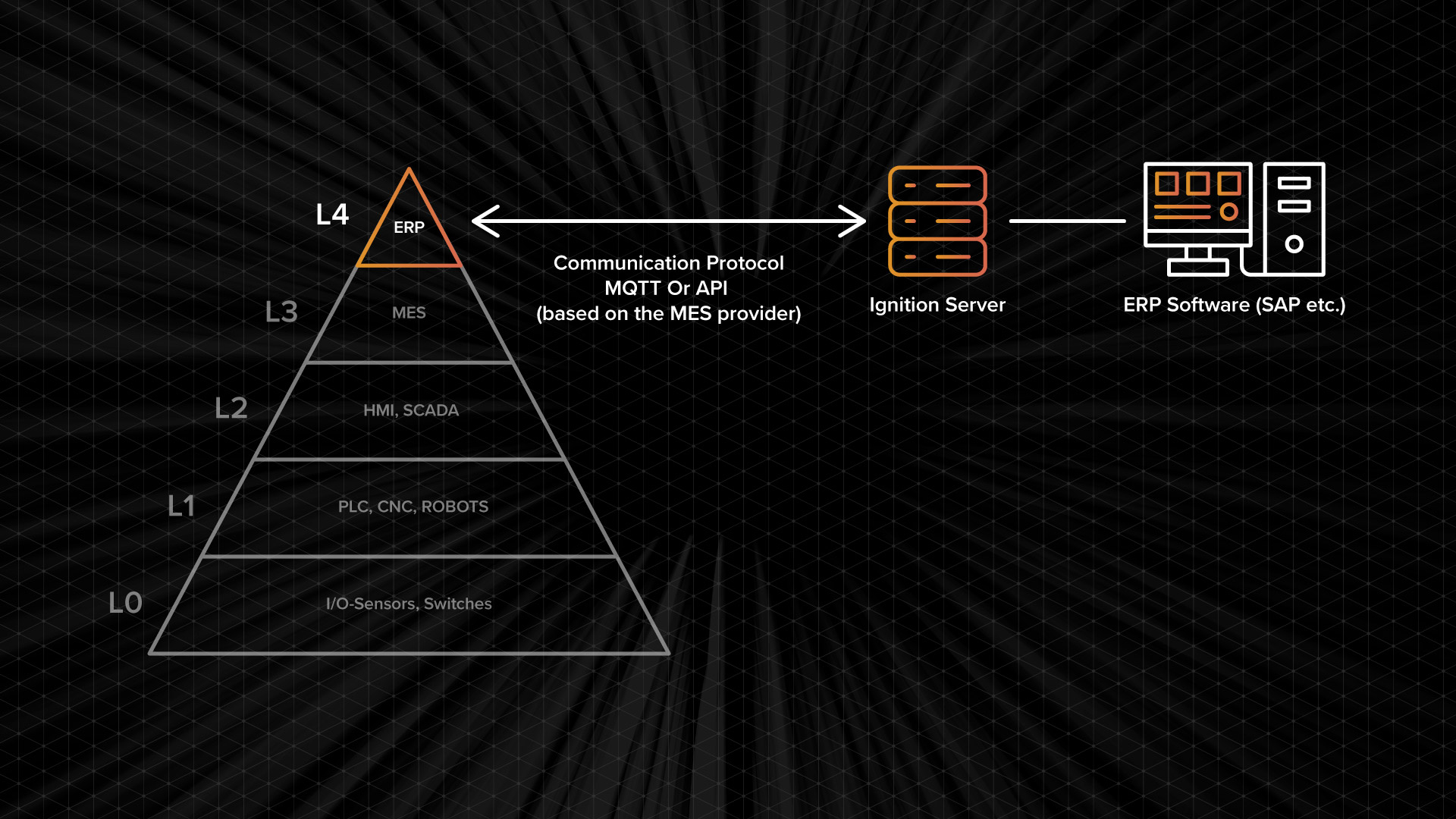

Layer 4: Management Layer

- The top of the pyramid is called the management level, also known as ERP. This level typically uses the company's integrated management system software.

- With the Sepasoft Business Connector, Ignition can connect to ERP systems like SAP or an existing ERP system that a plant may already have, or by using APIs and Ignition's Web Dev Module, which turns Ignition into an API endpoint for other systems to use.

Seamlessly Integrate With Ignition

Manufacturing processes have evolved over time according to changing customer needs. This has resulted in a variety of field devices on the shop floor with proprietary protocols, resulting in a lack of standardization and increased complexity when exchanging data between different layers of the Automation Pyramid.

By seamlessly integrating with different layers of the Automation Pyramid, irrespective of the make of the devices, Ignition ensures interoperability by being compatible with many open protocols and standards.