Sierra Nevada Brewing Co. Makes Ignition Its Go-To SCADA Solution

5 min video / 8 minute read Download PDFIt’s a strange problem when an IT department can put too many features on the system. Usually, it’s the other way around. More often than not, it is the IT department that is overwhelmed with requests.

“We find that we can overload our users with new features,” said David Lewis, business analyst for Sierra Nevada Brewery Co. “It’s so easy to build stuff. We’re way ahead of the user-curve. We have found that we have to wait for them to digest what we’ve built, and then wait for them to start asking for more.”

Lewis explains that before implementing Inductive Automation software, they had a lot of requests – and those requests took a long time to develop. Accessing production system data was the biggest IT development hurdle. There just wasn’t an easy way to get the data. After implementing the new software, they were able to easily obtain data from anywhere in the plant.

“Now, all of a sudden the data is all there,” Lewis said excitedly. “It’s the keys to the kingdom. We’ve now been able to manage some pretty heavy workflow problems.”

Getting Through the Skepticism

But it wasn’t initially easy to find those keys to IT bliss. Anytime IT makes a decision to put new software on a system, they need to proceed with caution to ensure no disruption to the plant’s production.

“We approached the software with skepticism,” Lewis explained. “There was no support among our automation engineers for using it as a control system for both philosophical and practical reasons: Philosophically, because we treat our control system as a stand-alone system – completely unconnected from any other network – and practically, because our corporate Windows-based PC network had such a rotten reliability record.

“Fermentation is a 24/7 process, so our plant controls staff were in no mood to introduce Windows-style downtime to their lives. The Inductive Automation software was so inexpensive, however, that we decided to try it for data acquisition and production reporting – two areas where there were no good alternatives on the market.”

The first experience with the software proved to be very user friendly.

“It was easy to configure,” explained Jonathan Swisher, system developer for Sierra Nevada Brewery Co. “The reason it’s easy is because I only had to install it on the server – one install. It took me no time, except installing it on the server. Its easiness comes from the client-side because there are no clients to install individually. There’s not a lot of overhead work to get it out to everyone in the plant.”

From a technical knowledge perspective, Swisher said the software had a very easy learning curve. It’s familiar to individuals trained in standard office technology such as web, Java, SQL databases, etc.

“Most of it seemed intuitive,” Swisher explained, referring to Inductive Automation’s “Jython” scripting. “All these functions are well documented. Python is clean and concise; which makes Jython really familiar. Jython is super easy to learn because it was familiar to what we learn in school.”

Access to Data Opened Up Possibilities

Ron Mayfield, system developer for Sierra Nevada Brewery Co., said that various interactions with the company’s SQL database had always been problematic in the past. When they rewrote all of the data to go through Inductive Automation’s software, life got easier.

“Once we realized that was possible – to work with the PLCs and other SQL production databases – we found we could bring it all together and put it on one screen,” Mayfield said. “That kind of synergy of info was all off limits until Inductive Automation came around.”

By being able to work with the PLCs and the database, Mayfield said they soon realized that they could help all departments communicate seamlessly. One example he gave was their filtration to packaging workflow.

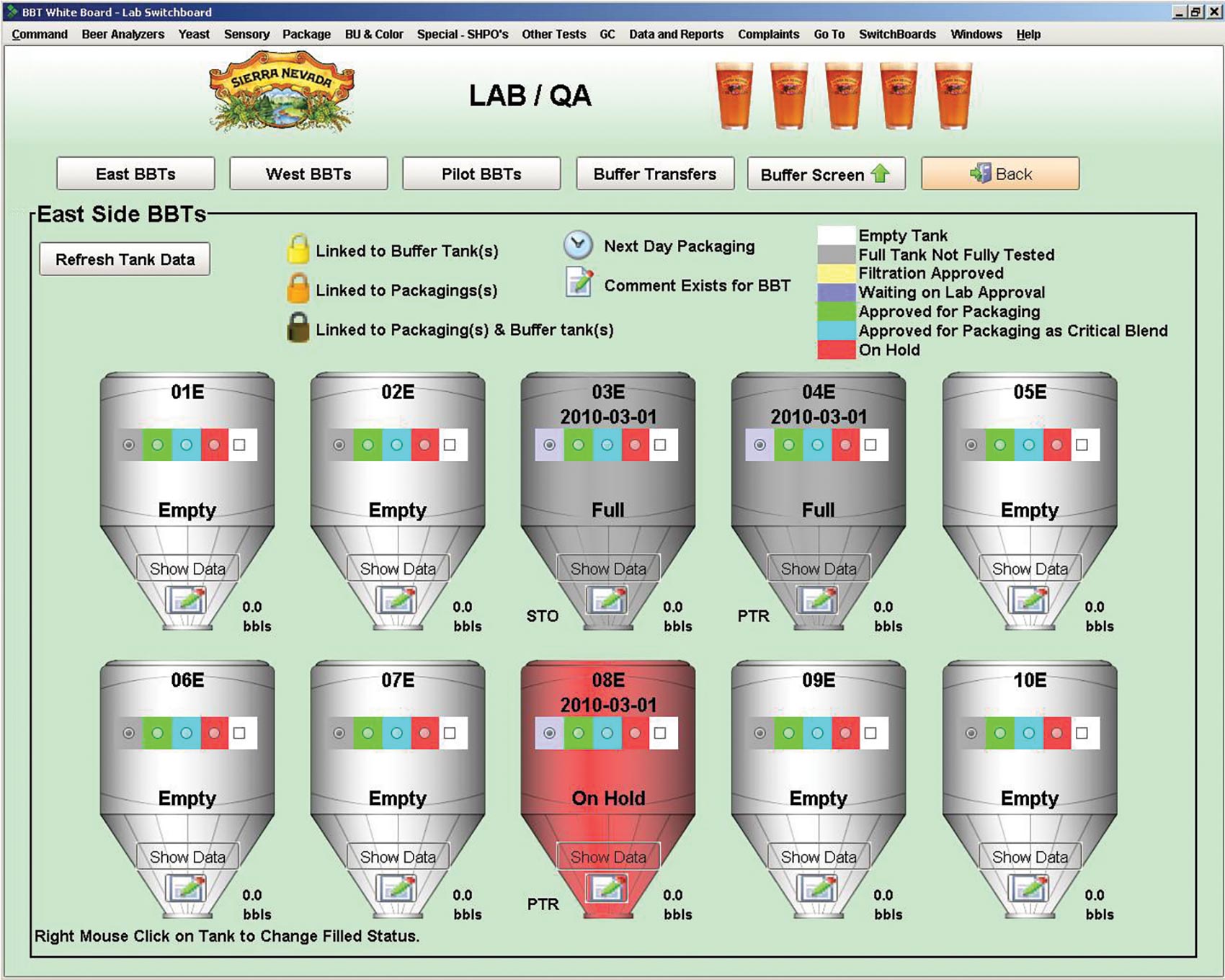

Before a tank of beer is ready to be packaged, it has to be processed by the filtration department and then sampled and tested by the lab. Test information was then hand-written on to a series of whiteboards around the plant.

Mayfield said they faced a very simple, but big problem: As the plant grew, people had to remember to write that information down in more and more places – a round trip of nearly half a mile! Now, with web-launched client screens bringing together PLC data (tank statuses, etc.), lab test data (from lab devices), and workflow data (approvals, comments, out of spec alerts), all that information is now available through any PC in the plant.

In Summary

Lewis, Mayfield, and Swisher agreed that changes aren’t always easy. Especially when the IT department can make more features than their users can take in at a time. They’ve actually had to slow down the pace of how many features they add to the system, just so users get a chance to accept the new changes.

“But I think everyone agrees that the changes are good,” Lewis said. “We’re a growing company. Five to ten years ago when we had to make a production decision, we would simply walk over and talk to someone … but now, you can’t always find that person. Using Inductive Automation’s software, we can always find the screen. Operation is much easier than before.”

Sierra Nevada Brewing Co. is the sixth largest brewery in the United States. Their beer is produced exclusively in Chico, Calif., and is distributed in all 50 states and exported to Europe and Asia. Their flagship product is Sierra Nevada Pale Ale, complemented by a year-round program of seasonal and specialty beers.

Transcript:

00:10

Ron Mayfield: My name is Ron Mayfield. I work for Sierra Nevada Brewery, and I use Ignition. Most breweries have a unique process. It's all generally the same, but everybody handles things a little differently. To have somebody write a customized application for you is expensive, and typically, at least at this facility, the processes change all the time. So you would continuously have to have those people come back, whereas we do updates on a constant basis.

00:53

Jonathan Swisher: My name is Jonathan Swisher. I am a Systems Analyst for Sierra Nevada Brewing Company. We were looking at a way to capture data from machinery or PLCs, and we had some other companies come in and showed their massive project that looked like it took thousands of hours to configure and cost hundreds of thousands of dollars to purchase and license. I think it was the packaging manager that heard of Inductive Automation. We piloted the software, and once it proved itself, we slowly just started adding other devices.

01:32

Ron Mayfield: We started pushing up that software to all our users, and everybody really liked it. Reports, graphs, charts, all the different areas of brewing information: cellaring, through-filtration, through-packaging, information from the lab, tracking trucks coming in and out of the yard now in real-time fashion using the Ignition software.

01:55

Jonathan Swisher: It grew with just fan-base requests. We then went to the brewhouse and started gathering data off of there. Then we went to packaging, the fermentors, people in our cellar department. But then we had everyone in the QA department starting to want to look at it. People in the brewhouse wanted to start looking at that data along with people further down the process. But as it rolled out to various departments by word of mouth, through the brewery, people wanted to look at that data. So Ignition allowed us to do that, where now you can just pull it up at your workstation and see what was going on at that time.

02:27

Ron Mayfield: It's interesting that once people start getting information and seeing what's possible, then they really want a lot more. It's a lot like clicking up Lego blocks or something. We have it hooked up to a lot of different things. It’s really easy to use. I can't think of any way that we would be using it that's unusual, but I think that's because we use it for everything. We're just using it in so many different ways. Every way seems normal at this point.

03:04

Jonathan Swisher: Prior to Ignition, the data was communicated through whiteboards throughout the plant. Somebody would walk around and update the whiteboard with information. So as the beer flowed from tank to tank and we did various things such as yeast cell counts or temperatures or CO2 values on the tanks, that information was written on whiteboards so people knew where it was in its process stage, mainly before it went to packaging or on its way out to packaging. So, now with Ignition, we can communicate that with the click of a mouse from one area of the brewery to another area of the brewery without somebody walking around and updating whiteboards.

03:42

Ron Mayfield: It's our go-to product. It really is. We use it for everything. I have absolutely never had anybody support like Inductive does. Just phenomenal support. I would call them up, or I would send them an email, and within an hour, I would get a resolution to any problem I had. I've had them write a special, a code snippet and send me the code for it and say, "This is how you should go about doing that," or, "Have you approached it a different way?" We might jump into a project we don't know how to accomplish to start off with. Knowing that when we get to that next point, there's somebody we can call and say, "How do we make this work?" It's nice to have that knowledge that I may not know how to do it, but I know somebody that does.

Want to stay up-to-date with us?

Sign up for our weekly News Feed.