SCADA Aids New Approach to Process Safety Studies and Training

Multivariate Simulation and Artificial Intelligence Improve Hazard Studies

5 minute read Download PDF

Safety training of industrial personnel is extremely important, and while most training techniques are well established, there’s always room for improvement. That’s why a Ph.D. project developed a new method of training within hazard and operability study (HAZOP). HAZOP examines a complex process or operation to identify and evaluate problems that may represent risks to people or equipment. Dynamic simulation uses software to show the different scenarios that could develop from a variety of conditions, and helps operators learn how to respond to potentially dangerous situations.

The Ph.D. project proposes a new approach that focuses on multivariate simulation training rather than univariate. In a univariate scenario, one failure at a time is considered. The multivariate approach looks at several at a time — scenarios that cause multiple failures and domino effects requiring a more complex analysis. Studies have shown that major accidents are often caused by multiple failures or domino effects.

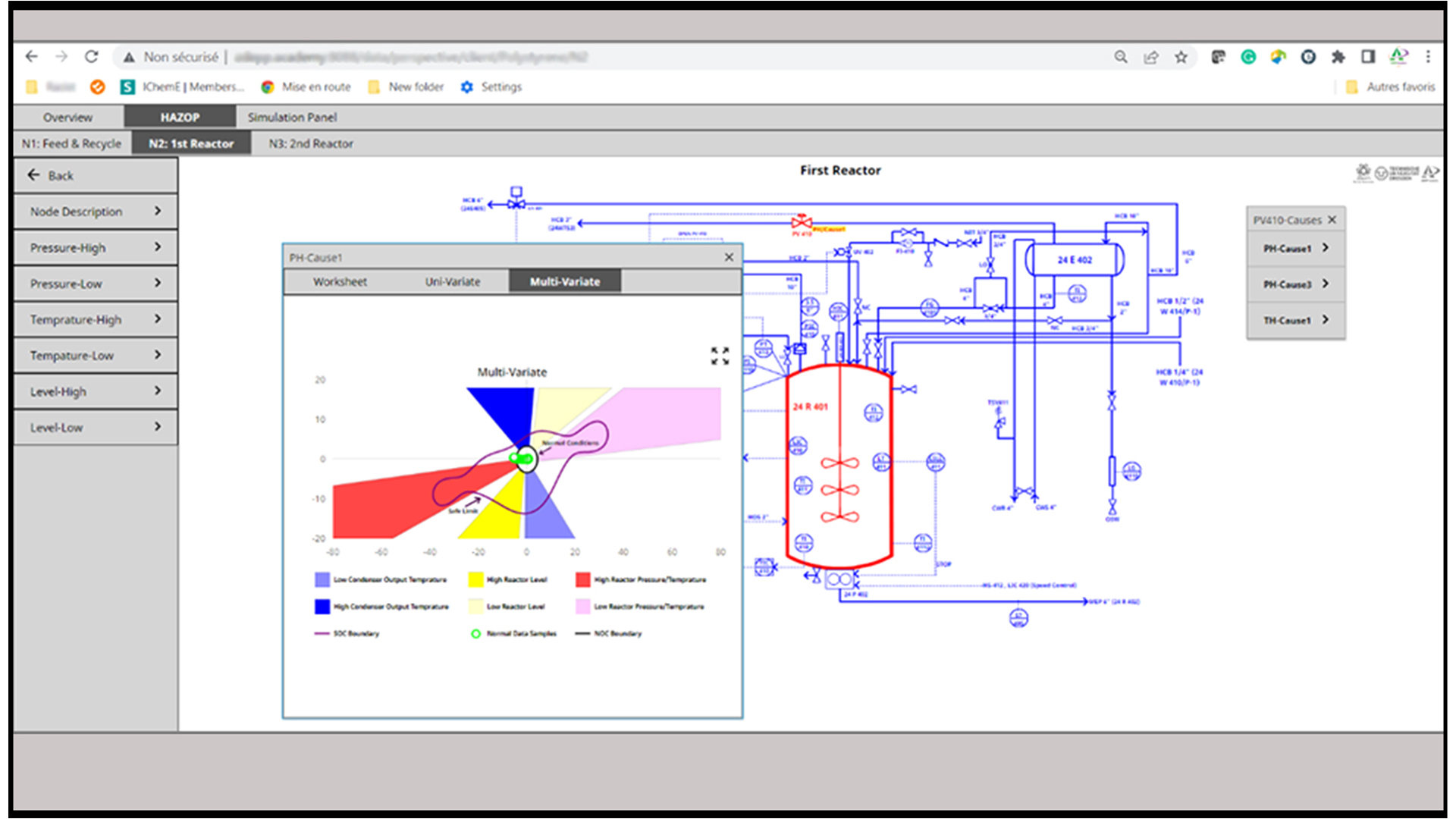

The multivariate simulation discussed in the Ph.D. project is built on Ignition by Inductive Automation® — an industrial application platform with tools for building solutions in supervisory control and data acquisition (SCADA), human-machine interface (HMI), and the Industrial Internet of Things (IIoT).

Novel Approach

“The main objective of this thesis was to propose a new systematic procedure to improve HAZOP analysis of complex processes,” said Reyhane Mokhtarname, the Ph.D. candidate. “The thesis suggests a more rigorous use of process simulators together with the power of artificial neural networks.” Mokhtarname has extensive experience in both academia and industry. Her work on her Ph.D. has been at Shiraz University in Iran and Technische Universität Dresden in Germany. ADEPP Academy is also involved in the project, as an industrial partner. ADEPP (Analysis & Dynamic Evaluation of Project Processes) is based in London and focuses on training and other services for a variety of industries.

“This is a new methodology, implementing system thinking, system engineering, and complexity management in HAZOP studies — and branding them as HAZOP 4.0,” said Fabienne Salimi, technical director and founder of ADEPP Academy. “This is a novelty that we are proposing with this multivariate monitoring.” The project has gone so well, she said, there are plans to expand the possibilities in the future. “Our intention is to apply this approach for all the typical, complex processes,” said Salimi, who has more than 30 years of experience as a chemical process engineer. The plan includes more use of artificial intelligence, to further enhance analysis.

The project has been highlighted at two international conferences, and a well-known publisher will put out a book on the subject in the second half of 2022. Salimi will be the lead author and will write the book with three colleagues. The title will be “A New Approach to HAZOP for the Complex Chemical Processes.”

Holistic Look at HAZOP

HAZOP takes a systematic approach to identifying hazard probabilities. The typical method is to use experience to learn and improve, but the univariate approach has limitations. “This approach can be effective only when we are looking at one failure at a time, which are simple hazard cases and the responses to them are well-known and can be found in the relevant standards, guidance, and checklists,” said Mokhtarname. “Subjectivity is another weakness of HAZOP studies. The quality and resolution of HAZOP studies is highly dependent on the knowledge and experience of the HAZOP team. A given case can be assessed very differently by two different HAZOP teams.”

Scenarios including multiple failures help operators see a bigger picture. “We apply multivariate monitoring,” said Salimi. “It can be more than one alarm at the same time, and you can see the holistic response of the system. And based on that we guide the operator to take the right action.”

Microsoft SharePoint is used for database management, brainstorming documentation, other HAZOP information, and more. “That’s the IT part,” said Salimi. “And OT is the Ignition part, which can be simulation, or simulated or real data from a plant.” The simulation programming is done in MATLAB, which connects to Ignition via OPC. Ignition also connects to the data in SharePoint, and Ignition is the platform for a digital twin of a real plant that is also part of the project. It’s a 25-year-old complex styrene polymerization plant that provides data to Ignition. The power of the solution brings traditional HAZOP to a higher level.

Powerful Tool

In the Ignition software, users can see diagrams and descriptions of the plant processes. They can choose a variety of deviations, such as high temperature, low pressure, and more. They can see a variety of causes for each deviation. Users can change variables to see how all trends are affected. Popups provide options to see worksheets, univariate simulations, and multivariate. The thesis proposes for the first time a second layer of decision boundary; in addition to normal operating conditions (NOC), the thesis proposes adding safe operating conditions (SOC).

Ignition is a good fit for the project, said Salimi. “Ignition can be used as a powerful tool for the research projects as well as professional training of operators,” she said. “And it can be used for design optimization, alarm rationalization, and troubleshooting, or required corrective action of the process upsets. This innovative approach enhances several elements within the Center for Chemical Process Safety’s Process Safety Management system. The elements enhanced by the new approach include process safety competency; knowledge management; hazard identification and risk assessment; operating procedures; training and performance assurance; management of change; and operational readiness.”

The book about this project will be published by Elsevier, a leading publisher based in Amsterdam. Along with Salimi, the authors will be Frederic Salimi of ADEPP Academy, Ali Akbar Safavi of Shiraz University, and Leonhard Urbas of Technische Universität Dresden.

Want to stay up-to-date with us?

Sign up for our weekly News Feed.