Revolutionizing Data Efficiency with Ignition and MQTT

As the Industrial Internet of Things (IIoT) revolutionizes data processes, many organizations are beginning to turn to open-source software like MQTT and Sparkplug B. Through Cirrus Link and Inductive Automation’s strategic partnership, organizations can efficiently streamline data collection, modeling, and usage with Cirrus Link’s MQTT modules and Inductive Automation’s industrial automation platform Ignition.

In this blog, we'll look at two companies that have successfully implemented Ignition, MQTT, and Sparkplug B into their operations to achieve higher efficiency, faster processing speeds, data standardization, and improved OT-IT integration.

Our first case study tells the story of a solar company that used Ignition, MQTT, and Sparkplug to standardize and decouple data, provide context for data, and handle extreme data loads. The second case study showcases how an agricultural equipment manufacturer used these solutions to better send and receive data, improve data modeling, perform useful analytics, and provide the best data to their data scientists in real time.

Solar Tech Company Achieves Efficient Data Transfer to Improve Operations at Solar Farms

Overview: A solar technology company aimed to gather a large amount of data from 200+ solar farms to improve operations. The data would be analyzed and used for energy management, to increase productivity, and to improve efficiency across the business. Facilities were remote and data loads were extreme, so the solution needed to handle data with a small, efficient footprint with the ability to send data upon change to reduce the amount of data being sent and improve the speed of data transmission.

Project Goals and Challenges

Not only did the customer have more than 200 solar farms, but they also had more than 100,000 data tags to collect at each site, resulting in more than 2 million total tags to collect. Some data was changing every second. They also had multiple consumers of the data — a control center and cloud services using Apache Kafka for high-performance data pipelines and integration.

The customer was not getting the results they needed collecting data from the solar farms with typical poll/response protocols such as OPC UA. The current system was inefficient for the large amounts of data they were trying to consume — bandwidth usage was extremely high, and the customer couldn’t retrieve the data fast enough to meet their requirements.

The goal was to adopt a solution that could poll for data locally and deliver the data needed rapidly, with context, and with greater efficiency. The customer wanted to reduce bandwidth usage, improve data throughput and reduce processing requirements.

Implementation

The customer chose to build their architecture around open standard tools for a future-proof solution that would keep them from being locked in to any one vendor. They chose the MQTT protocol to transfer large amounts of data with greater efficiency.

Specifically, MQTT could do two things for them:

- Standardize the data and decouple data for multiple consumers

- Provide contextualization on the data with MQTT Sparkplug

MQTT is a proven, standard machine-to-machine data transfer protocol that is quickly becoming the leading messaging protocol for Industrial IoT. MQTT was ideal for this use case as a publish/subscribe, extremely simple, and lightweight messaging protocol ideal for constrained networks.

Sparkplug B is an open-source software specification that defines how to use MQTT in a mission-critical, real-time environment. The Sparkplug B specification provides the data model needed to define a tag value for use with OT, also providing data to IT, making it 100% self-discoverable and easy to consume. Sparkplug was also ideal for this use case because it has a built-in store-and-forward mechanism to send data across the network to be consumed not only by the control center but also the cloud service via Kafka.

Kafka is an Apache open-source distributed event streaming platform for high-performance data pipelines and data integration. A Kafka connector subscribes to the MQTT Sparkplug data and enables it for tools like Power BI and Grafana so the customer can do visualizations and more advanced analytics.

The company chose the Ignition SCADA platform as the central control system for its connectivity capabilities in unison with Cirrus Link MQTT modules. Ignition connects to all the sensors at the solar farms, then uses the Cirrus Link MQTT modules to transfer that data to a central location and integrate into Kafka so they can use it to optimize production with machine learning and other advanced analytics.

Results

The new architecture built around MQTT and Sparkplug gave the customer a standardized, efficient platform for data movement. The solution allowed the customer to move data securely and efficiently from the OT layer upstream to Kafka. Data can now be sent by exception, meaning only on change, which improved throughput over the network by more than 80%. Instead of sending 3 million tags with a round-robin poll, they send 5 to 10% of that by sending only on change.

The solar technology company also greatly reduced central processing time since the data producers and consumers are now decoupled via MQTT, so the data can go to multiple consumers at once. All the data is also self-discovered automatically following the Sparkplug data format.

The project scaled rapidly, and they rolled the solution out to 150 sites in the first year alone, with the other half set to roll out in year two.

Agricultural Equipment Manufacturer Enables Predictive Maintenance and Increases Efficiency with MQTT and Sparkplug

Overview: A manufacturer of agricultural equipment sought an Industrial IoT solution to help them collect data and use it to implement advanced analytics and predictive maintenance, and ultimately run their facilities more efficiently. They set out to adopt a solution that would accomplish those goals by unifying OT systems and getting the right operational data to their data scientists so they could use it for improved and efficient operations.

Project Goals and Challenges

At the highest level, the agricultural manufacturer was focused on digital transformation to continuously improve efficiency across their many factories. In order to accomplish these goals, they needed to provide the right data to their data scientists in near real-time to perform advanced analytics and enable better business decisions.

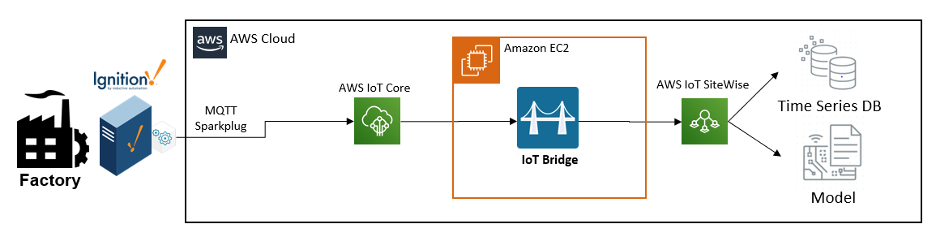

They had several facilities with different processes and varied equipment. They had adopted AWS as their cloud solution but did not have a standard way to get the data models into AWS IoT SiteWise.

The customer identified various use cases for the project from predictive maintenance to AI, but the key was to first put the right technology pieces in place with a standardized way to model all plant processes and assets and provide a single source of truth for OT data. Until they solved these OT-IT integration challenges, their data scientists could not get the full value out of SiteWise.

Solution Requirements

The customer had AWS IoT SiteWise for a few years, which is a managed service designed to collect, model, analyze, and visualize data from industrial equipment at scale. The next step after adoption was to solve their data modeling challenges.

At the foundation, they needed a modern SCADA system to maintain, manage and control their OT assets and gather data from them, then interface with SiteWise for further value. They also needed a piece in the middle between the SCADA system and AWS SiteWise to handle the data standardization and data modeling piece seamlessly.

Since they had multiple facilities with various processes and equipment, they needed a solution that could work on-premises, then standardize and send the OT data to a central system for AWS integration across many factories.

Implementation

The customer chose the Ignition SCADA platform as the central control system for its robust, high-availability toolset for data acquisition, real-time status and process controls, optimized HMIs, alarms, and analytics. They appreciated the ability to customize the modular solution, and powerful visualization tools were also part of the decision.

Cirrus Link Solutions offers MQTT Modules for Ignition to integrate or push data from OT to IT. The IoT Bridge for SiteWise, in particular, delivers OT data from industrial applications to SiteWise with minimal configuration and zero coding. Cirrus Link’s IoT Bridge for SiteWise was the perfect piece in the middle the customer needed to bridge the OT-IT gap.

The best thing about the deployed solution is the agricultural manufacturer can simply point the Cirrus Link module at the AWS IoT service and the asset model; properties and hierarchy are 100% self-discovered by SiteWise. As a result, they can easily connect to OT data, gain access, then start delivering standardized data models in real-time to SiteWise so they can use it for advanced use cases like predictive maintenance and AI.

At its core, the solution is based on the MQTT protocol and Sparkplug B specification. Because MQTT is time-tested, lightweight, and uses a simple publish/subscribe messaging protocol, it was an ideal for this use case. And Sparkplug B allowed the definition of tag values so they could be used with OT while providing data to IT.

Results

The agricultural equipment manufacturer is now using Ignition, Cirrus Link, and the MQTT and Sparkplug technology at their local sites to model data at the plant level and then send it upstream. They now have a standardized way to define all of the data models within their facilities so they can publish them via Sparkplug into AWS SiteWise.

Now, with the right OT data in SiteWise, their data scientists can query that data, perform analytics, and power their use cases for improved operations, including more uptime, reliability, predictive maintenance, and more.

The real benefit is they have a simple, no-code solution to make this happen seamlessly. They have now achieved OT-IT integration and the data science team can build real value on top of the data.

Leveraging IIoT Solutions for Efficiency and Future Innovation

As organizations integrate open-source IIoT software such as MQTT and Sparkplug B with existing systems, they will be able to better streamline their data processes. Cirrus Link’s MQTT modules and the Ignition platform provide a simple way to adopt IIoT solutions that provide extensive data modeling, transfer, and usage improvements. Together, these solutions have allowed top companies in oil and gas, pharmaceutical, hydroelectric, and other industries to gather, analyze, and standardize large amounts of data, improve efficiency, and future-proof their systems.

To learn more about Cirrus Link’s MQTT modules for Ignition, click here.